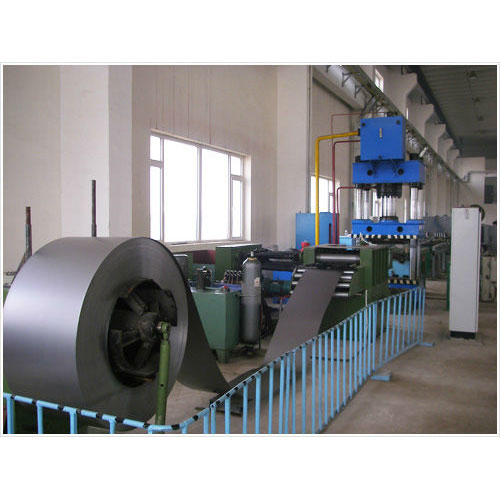

Transformers radiator automatic production line is developed base on the absorption of the German Georg and Canada MTM technology. The whole production line is mainly consisted of the automatic decoiler, rolling and forming machine, combined flip-chip platform, multi-spot welding, seam welding , endings welding, rolling cut machine, head cutter and related transfer racks. Produce width 520 and 460 sheet(according to customer needs.) and any size within the range of center distance 500mm-4000mm. High degree automation, good forming quality, its performance has reached the similar level of well known manufacturers in the world. It's the ideal processing equipments for radiator manufacturers. The production line can also be used as flow line or independently ( center distance below 1200mm it’s better to use independently).

Production process: Coil loading- Automatic decoiling - Rolling – Hydraulic forming - Automatic chip combination - Multi –spot welding – Bilateral seam welding - endings welding – Bilateral rolling cut – head cutting – final radiator chip.